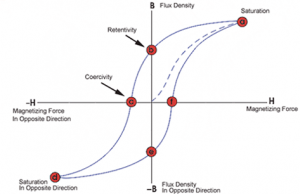

Permeability is the measure of the resistance of a material against the formation of a magnetic field. It is a measure of the magnetization that a material obtains in response to an applied magnetic field. Magnetic permeability is typically represented by the Greek letter μ. In general, permeability is not a constant value, as it can vary with the position in the medium, the frequency of the applied magnetic field, humidity, temperature, and other criteria. In a nonlinear medium, the permeability can depend on the strength of the magnetic field. Permeability as a function of frequency also addresses real or complex values.

A closely related property of materials is magnetic susceptibility, which is a dimensionless proportionality factor that indicates the degree of magnetization of a material in response to an applied magnetic field.

About Permeability Units

In SI units, permeability is measured in henries per meter (H/m), or equivalently in newtons per ampere squared (N⋅A−2). The permeability constant μ0, also known as the magnetic constant or the permeability of free space, is a measure of the amount of resistance encountered when forming a magnetic field in a classical vacuum.

Until 20 May 2019, the magnetic constant had the exact (defined) value μ0 = 4π × 10−7 H/m ≈ 12.57×10−7 H/m.

On 20 May 2019, a revision to the SI system went into effect, making the vacuum permeability no longer a constant but rather a value that needs to be determined experimentally; 4π × 1.00000000082(20)×10−7 H⋅m−1 is a recently measured value in the new system. It is proportional to the dimensionless fine-structure constant with no other dependencies.

In 2019, the SI base units were redefined in agreement with the International System of Quantities, effective on the 144th anniversary of the Metre Convention, 20 May 2019. In the redefinition, four of the seven SI base units – the kilogram, ampere, kelvin, and mole – were redefined by setting exact numerical values for the Planck constant, the elementary electric charge, the Boltzmann constant, and the Avogadro constant, respectively.

In electromagnetism, the auxiliary magnetic field H represents how a magnetic field B influences the organization of magnetic dipoles in a given medium, including dipole migration and magnetic dipole reorientation. Its relation to permeability is

where the permeability, μ, is a scalar if the medium is isotropic or a second rank tensor for an anisotropic medium.

Relative permeability and magnetic susceptibility

Relative permeability, denoted by the symbol  , is the ratio of the permeability of a specific medium to the permeability of free space μ0:

, is the ratio of the permeability of a specific medium to the permeability of free space μ0:

4π × 10−7 N⋅A−2 is the magnetic permeability of free space.

4π × 10−7 N⋅A−2 is the magnetic permeability of free space.

In terms of relative permeability, the magnetic susceptibility is

The number χm is a dimensionless quantity, sometimes called volumetric or bulk susceptibility, to distinguish it from χp (magnetic mass or specific susceptibility) and χM (molar or molar mass susceptibility).